Views: 0 Author: Site Editor Publish Time: 2025-12-18 Origin: Site

Waterproof laminate flooring is an advanced laminate flooring solution engineered to resist moisture far beyond traditional laminate products. From a manufacturer’s perspective, it represents a balance between natural wood aesthetics, controlled water protection, and cost efficiency—qualities that make it increasingly popular in global residential and light commercial projects.

At Licheer, we view waterproof laminate flooring not as a passing trend, but as a response to real market demands: better performance, fewer installation complaints, and greater flexibility for distributors and project clients.

Across international markets, end users want floors that look like wood but behave more predictably in daily life. Spills, humidity, and temperature fluctuations are unavoidable, especially in modern open-plan spaces.

Waterproof laminate flooring addresses these realities by strengthening the weakest link of traditional laminate—moisture resistance—while maintaining familiar structure, appearance, and pricing. For B2B buyers, this translates into fewer callbacks, broader application potential, and higher customer satisfaction.

From a manufacturing standpoint, “waterproof” does not mean unlimited water exposure. Instead, it refers to engineered resistance—the ability of the surface, joints, and core to delay or prevent water penetration for a defined period of time.

This distinction is critical for distributors, specifiers, and project planners, as it sets proper expectations and reduces misuse on job sites.

Water-resistant laminate provides short-term protection against minor spills. Waterproof laminate goes further by incorporating sealed joints, hydrophobic surface coatings, and treated cores that significantly slow water absorption and improve real-world performance.

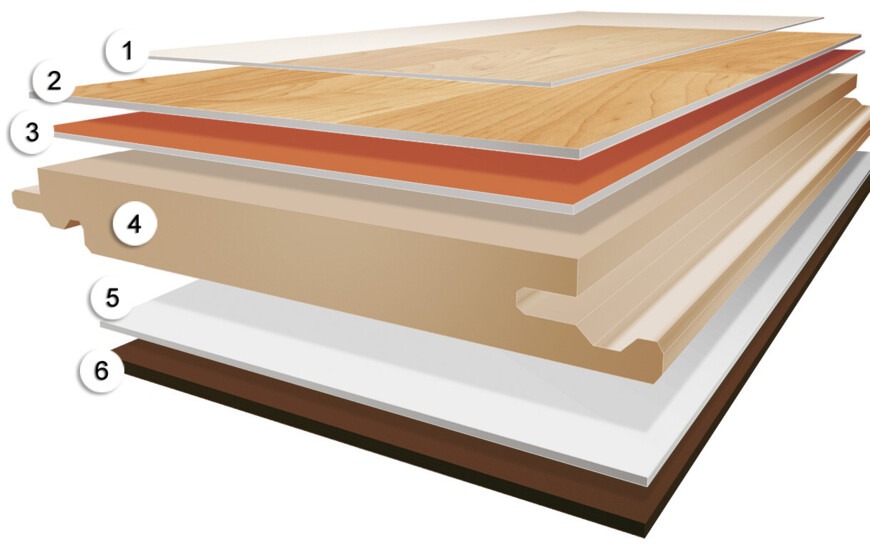

Waterproof laminate flooring relies on a multi-layer structure. Each layer plays a specific role, and manufacturing precision determines how well the final product performs in the field.

The wear layer is treated with advanced coatings that repel liquids, resist scratches, and protect the decorative layer below. Higher AC ratings are achieved through controlled abrasion testing and surface reinforcement.

High-definition printing technology allows manufacturers like Licheer to deliver consistent wood visuals across large batches—an essential requirement for project continuity and repeat orders.

The core board defines how the flooring reacts to moisture, pressure, and environmental changes.

Waterproof laminate typically uses high-density HDF cores engineered to reduce swelling and improve load-bearing performance.

Hydrophobic treatments are applied during production to slow moisture absorption and enhance short-term water resistance.

The backing layer stabilizes the plank and provides additional protection from subfloor moisture, especially in renovation projects.

Sealed surfaces and tight joints reduce water penetration at plank edges—historically the weakest point of laminate flooring.

Improved core density helps minimize expansion and contraction caused by temperature and humidity fluctuations.

Waterproof laminate flooring is commonly produced with AC3–AC5 ratings, making it suitable for residential and light commercial environments.

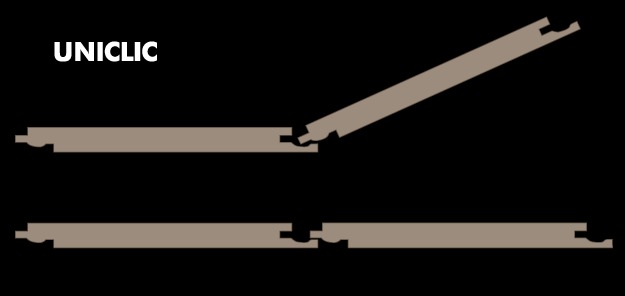

High-precision locking systems ensure tight seams, contributing directly to water resistance and installation reliability.

Waterproof laminate can now be specified in kitchens, corridors, and other moisture-prone areas once unsuitable for laminate products.

Compared to vinyl, laminate flooring often delivers a warmer, more authentic wood appearance—an important factor in many markets.

For large-scale residential and hospitality projects, waterproof laminate offers an effective balance between performance and budget.

Laminate flooring is lighter, more stable, and easier to transport, reducing shipping risks and costs.

Waterproof laminate can handle spills, but prolonged standing water should always be avoided to protect the core.

A flat, dry subfloor is essential. Installation quality directly affects long-term performance.

Vinyl flooring is fully waterproof through its core, while laminate offers superior realism and a more natural underfoot feel.

SPC flooring provides complete waterproof performance, while laminate remains competitive in warmth, acoustics, and cost positioning.

Waterproof laminate significantly outperforms traditional laminate in moisture resistance and application flexibility.

Ideal for apartments, houses, and renovation projects where moisture resistance and aesthetics are both required.

Suitable for offices, hotel rooms, and retail spaces with moderate foot traffic.

Manufacturers recommend strict subfloor flatness and moisture control to ensure long-term stability.

Proper acclimation and expansion gaps are essential for consistent performance across different climates.

Routine sweeping and damp mopping with neutral cleaners are sufficient. Excessive water and harsh chemicals should be avoided.

Always verify abrasion ratings and compliance with target market standards.

Board density and thickness directly impact stability, sound performance, and perceived quality.

A precision locking system reduces installation errors and water ingress risks.

Reliable manufacturers like Licheer provide consistent quality, branding flexibility, and long-term supply stability.

Waterproof laminate is not flood-proof. Clear communication between manufacturers, distributors, and end users prevents misuse and dissatisfaction.

If your project requires wood aesthetics, improved moisture resistance, and controlled costs, waterproof laminate flooring is a practical and competitive solution.

Waterproof laminate flooring represents a refined answer to modern flooring demands. When engineered with quality materials, precise processes, and realistic expectations, it delivers strong value for distributors, developers, and project partners worldwide.

Choosing the right product matters—but choosing the right manufacturer matters even more.

Next-Generation Flooring Materials in 2026: SPC 2.0, Hybrid Cores & Bio-Based Innovation

Sustainable Flooring Trends in 2026: From Green Claims to Real Performance

Smart Manufacturing in the Flooring Industry: How Digitalization Is Reshaping Quality and Efficiency

Flooring Industry 2026: Material Innovation & Smart Flooring Solutions